Coating nzira

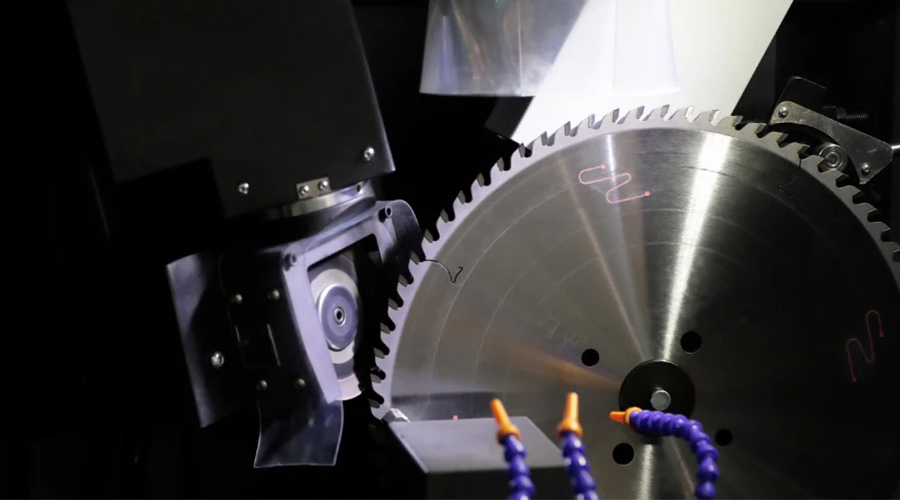

Parizvino, iyo huru yakashandiswa bladen coating nzira dzakasimwa chemakemikari Comication (PVD)

(1)CVD (Chemical Vapor Deposition)

Uimba iyo vaporbladeSubstrate. Iyo CVD inobatanidza maitiro ine tembiricha yakanyanya, yakasimba, asi inogona kuunza matambudziko akadai sekusara kwetsile kushushikana.

(2)PVD (Mupumbi Vapor Deposition)

Pasi peVafuum mamiriro, akaderera voltage, yakakwira iripo arc discharge tekinoroji inoshandiswa kudzima zvinhu zvinangwa uye kujekesa negesi, iyo yakaiswa panebladeSubstrate uchishandisa iyo inosimudzira mhedzisiro yemunda yemagetsi. iyo PVD inobatanidza ine tembiricha yakadzika (300 ~ 500 ° C), iyo isingazokuvadza kuomarara uye kurongeka kweiyobladeSubstrate, uye kuunganidzwa kune huwandu hwakanyanya hwekuchena uye kurongedza, uye zvakasungwa zvakasimba kune substrate.

(3)PCVD (Plasma Chemical Vapor Conforition)

Uchishandisa plasma kusimudzira makemikari maitiro uye kuderedza tembiricha yekubatanidza kusvika pazasi 600 ° C. Izvo zvakakodzera kuti nguva dzisiri kusarudzika kana kuchinjanisa maitiro hazvisi nyore kuitika pakati peiyo carbide subbide subbide uye iyo yekubatanidza zvinhu.

(4)IBAD (ION DEAM ADZIDZWA DZOKUDZIDZA TEXIGY)

Paunenge uchiisa kuunganidza muchikamu chechando, bombard iyo inoramba yakapihwa zvinhu neiyo danda reimwe simba rekuvandudza simba rekubatanidza pakati pekuvhara uye substrate.

Zvakanakira kuunganidzwablades

lKuvandudzwa kupfeka kurwisa: Chinyorwa chekuvhara chine kuomarara kwakanyanya uye kupfeka kurwisa, kuwedzera zvakanyanyabladeHupenyu.

lKuvandudzwa oxidation kuramba: Tanokwereta zviito semakemikari uye anopinza chipinganidzo, kuderedza kusiyana uye makemikari maitiro pakati pebladeuye basa rekushandira.

lKuderedza kupokana: COatings ine yakaderera coefficient yekukakavara, ichivandudza nzira yekucheka uye nemachina.

lWedzera simbi yekupera simba: Zvishandiso zvakaburitswa zvinobudirira kuramba kupera simba kupaza.

lWedzera inopisa kuvhundutsa: TIye anovhara zvinhu ane yakanaka yekugadzikana uye inoshandura kune yakanyanya kupisa tarisiro nharaunda.

lInodzivirira Corrosion.

Wedzera hupenyu hwechigadzirwa: BLade COTings inogona kuvandudza kujaira, kukuvadza kupokana uye zvakazara blade mashandiro, uye banga rekurudyi rinobatanidza rinogona kubatsira kuwedzera hupenyu hwekucheka kwemaindasitiriblades, izvo zvakakosha pakuderedza nguva yekudzvanya uye kugadzirisa kushanda zvakanaka.

Iwe unofanirwa kufunga nezvezvinhu zvinotevera usati wasarudza blade coating

(1)Chigadzirwa Shandisa

Chekutanga, zvakakosha kuti uzive kuti chigadzirwa chacho chichashandiswa, sekudya kwekudya, eturospace yekugadzirisa, uye kana iwe uchireva zvekutamba Ticn naTeflon vakanyanya blade machira ayo asiri-ane chepfu uye fad-compliant kana anotendera kuti uvashandise mukugadzirisa kusvibiswa kwechigadzirwa chako nemakemikari anokuvadza. Kana yako indasitiri inoda blades inochinjika, yeDLC yekudzora uye yakaoma chrome isarudzo yakanaka kwazvo.

(2)Ita shuwa kuti maburi akakwira mhando

Pamusoro pekutsvaga mhando kubva kumugadziri, iwe unofanirwa kuve nechokwadi kuti mapanga ako akakwirira emhando usati waisa coting. Kunyangwe neyemhando yepamusoro yekuvhara, banga remhando yepamusoro haingagare kwenguva refu, uye izvi zvinogona kukanganisa kushanda kwekubatirana. Kana iwe uchida kuita iyo yakawanda yeblade jasi, iwe unofanirwa kuve nechokwadi kuti unotanga nemapanga emhando yepamusoro maindasitiri.

(3)Performance zvinodiwa

Izvi zvinosanganisira kuomesa, kupokana nekuroora, kuramba, kuramba kupokana, kuora mwoyo kupokana, etc. Izvi zvinodiwa zvekuita zvichasarudza mhando yekuvhara zvinhu.

(4)Mutengo unofungidzirwa

Mari yemutengo wekubatanidza zvinhu uye coating nzira zvakare zvakakosha kufunga kana uchiita sarudzo.

Mhedziso

BladeCoating tekinoroji ndiyo nzira inoshanda yekuvandudzabladekuita, wedzerabladeHupenyu, kuvandudza kucheka zvakanaka uye kuchina chekodhi. Kuburikidza nekusarudzwa kwekusarudza kwakakodzera kuunganidza zvinhu uye nzira dzekubatanidza, coatedblades nekuita kwakanaka kuita kwakaringana kunogona kugadzirira kusangana zvakasiyana siyana zvekugadzirisa zvinhu. Mune ramangwana, nekuenderera mberi kwehunhu uye kukura kweanoshanda tekinoroji, yakachinjikablades ichatamba yakakosha basa muindasitiri yekugadzira.

Ndizvo zvese zvechinyorwa ichi. Kana iwe uchida the indasitiri blades kana uine mimwe mibvunzo nezvazvo, unogona kubata nesu zvakananga.

Gare gare, Isu ticharamba tichivandudza ruzivo, uye iwe unogona kuwana rumwe ruzivo pane yedu webhusaiti (Pastotoall.com) BLOG.

Ehe, iwe unogona zvakare kuteerera kune yedu yepamutemo yehurumende media:

Kutumira Nguva: Oct-18-2024